Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

When the world first glimpsed a sleek, silent helicopter‑like plane soaring above San Francisco on a sunny afternoon, it felt like a scene straight from a sci‑fi film. That vision is no longer distant fantasy—in fact, the first commercial eVTOL (electric vertical‑takeoff and landing) flight just landed at the Los Angeles International Airport, turning the dream of “air taxis” into a tangible reality. Headlines across international news, Tweets from aviation enthusiasts, and live streams from the event have captured a global audience that’s now seriously talking about how our cities will look—and move—differently. Within this electrifying buzz lies a crucial, often overlooked component: the gear motor, or reducer motor.

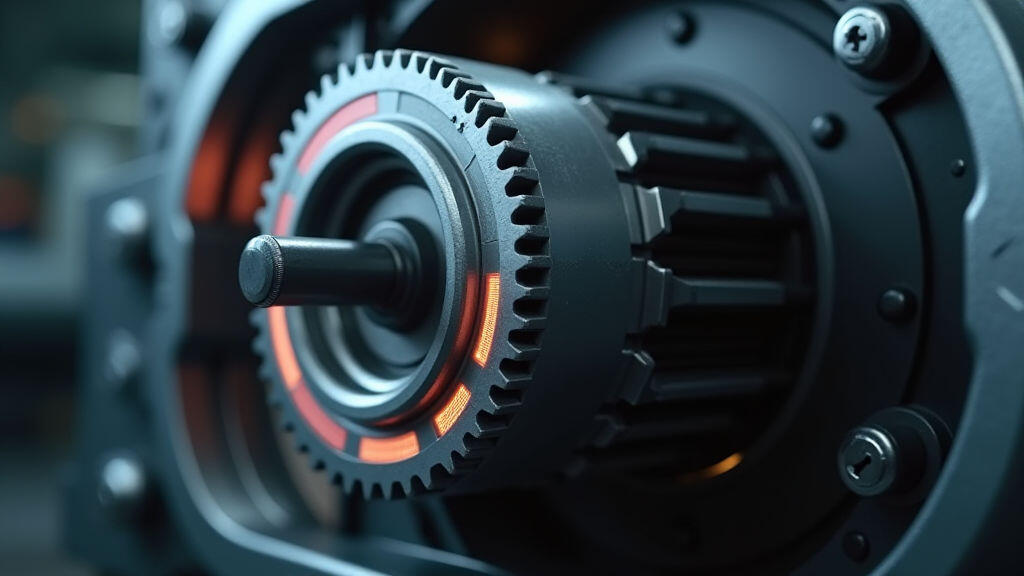

Gear motors convert the high‑speed, low‑torque rotation of electric motors into the low‑speed, high‑torque motion that turns propellers or rotor blades. Their role is nothing short of vital for the emerging eVTOL market, which demands precise, reliable, and energy‑efficient power delivery in a compact package.

The shift toward electric propulsion in the aviation sector has surprised many industry insiders. While electric cars have been the poster child for sustainable motoring, the same technology is now poised to rewrite urban commuting. eVTOL aircraft—designed to take off and land vertically—can circumvent traffic congestion, reduce travel time, and lower emission footprints. Companies like Lilium, Volocopter, and the newly announced Tesla Light are pouring billions into prototypes that could dominate the airspace above major metros by the early 2030s.

The power system of an eVTOL aircraft is a delicate balance between battery weight, energy density, and motor efficiency. Modern electric motors deliver high shaft speeds, but propellers or rotor blades must spin at much lower, more controllable speeds to generate lift and thrust. This mismatch is where gear motors step in. By reducing rotational speed while enhancing torque, gear motors allow the batteries to operate at optimal efficiencies, thereby extending flight range and service life. Their compactness also frees up vital cabin or payload space in a chassis already jammed with batteries, avionics, and safety systems.

In practice, a gear motor serves as the final stage in a cascade of power conversion: the battery powers a high‑speed electric motor → the gear motor modifies speed and torque → the rotor or propeller delivers lift. Without a properly sized reducer, an eVTOL would either suffer from excessive battery drain or overtax its structural components, both unacceptable outcomes for a commercial service.

Industry analysts predict that the eVTOL segment could reach an annual production volume of 10,000 units by 2030. Each aircraft may require anywhere between 12 and 24 gear motors depending on its design, representing a new, high‑growth market for manufacturers of reducer motors. Supply‑chain experts underscore how this market shift will drive innovation in torque processing, weight optimization, and thermal management—crucial parameters for both safety and efficiency.

From an economic perspective, gear motors are a cost‑effective upgrade over conventional direct‑drive solutions. Traditional vertical‑lift aircraft use large, low‑speed souffler wheels or mechanical transmissions that are bulky and heavy. In contrast, modern gear motors can achieve the same output torque with less mass, cutting a significant portion of the overall vehicle weight. For eVTOL operators, lighter weight translates into lower operating costs, higher passenger capacity, and more flexible route planning— all key selling points in the competitive urban air mobility space.

Several technological trends are converging to shape the next generation of gear motors for eVTOLs:

Miniaturization and Lightweight Materials

Advances in composite alloys and ceramic bearings are enabling gear motors that weigh a fraction of their legacy counterparts. A typical motor for a 5‑passenger eVTOL could weigh less than 10 kg, drastically reducing the energy penalty normally associated with transmission systems.

Smart Diagnostics and Predictive Maintenance

Integrated sensors now allow per‑gear health monitoring. Data analytics can predict mechanical wear before failure, a critical feature for safety‑critical aircraft. These “digital twins” ensure that every gear motor meets certification standards for continuous operation in harsh aerial environments.

High‑Efficiency Gear Ratios

Recent research in planetary and conjugate gear systems has boosted efficiency beyond 96%. For electric aircraft where every watt matters, this incremental improvement can extend flight range from 80 km to over 120 km— a substantial leap toward a viable network of air taxis.

Integration with Electric Propulsor Architectures

Gear motors are now being co‑designed with propellers, allowing manufacturers to split the load across multiple smaller motors. This modular approach enhances redundancy—a critical safety feature—and simplifies maintenance workflows.

In the near future, we are likely to witness a tight collaboration between aerospace firms and gear motor producers. Some eVTOL developers are already forming joint ventures to co‑develop custom reducer solutions, ensuring that the motors match their unique aerodynamic profiles. Additionally, the FAA and EASA regulators have introduced streamlined certification pathways for modular powertrain components, provided they meet standardized safety benchmarks. This regulatory momentum lowers barriers for gear motor suppliers to enter the eVTOL market and accelerates the pace at which efficient motors can reach the skies.

On the supply side, major gear motor manufacturers are investing in production lines capable of 3D printing complex gear geometries— a technique that reduces lead times and allows rapid prototyping of new designs. The convergence of additive manufacturing and high‑quality surface finishing is a game changer for delivering precision, cost‑effective, and reliable gear motors to the demanding eVTOL sector.

The soaring eVTOL industry marks one of the most profound shifts in urban mobility in recent decades. While its promise is loudly celebrated abroad, the mechanics that will make it a reality lie largely beneath the surface. Gear motors, those unsung heroes of speed‑torque conversion, are at the very heart of this transformation. Their capacity to reduce high‑speed electrical current into the precise, controllable motion required for lift and thrust is what will keep an eVTOL aircraft efficient, safe, and economically viable.

As cities brace for airborne taxis and regulators streamline approval procedures, the demand for advanced gear motors is set to accelerate alongside the eVTOL trajectory. For manufacturers, engineers, and investors, this trend presents a golden opportunity: to develop lightweight, high‑efficiency reducer motors that will not only power the next generation of aircraft but also help lower our collective carbon footprint. The sky is no longer the limit— it’s just the beginning of a new chapter in everyday transportation.

Leave A Reply

Your email address will not be published. Required fiels are marked